|

| Bernina 730 Record |

This machine was listed on Craigslist near me and the buyer asked for reasonable offers. I submitted my best offer and the seller informed me that he was going to see if he got any better offers and would get back to me. Since the machine came with accessories, original case, foot control, and extension table I knew that there would be other interested buyers. A week later, I emailed to see if the machine was still available and the seller agreed that I could buy it for my original offer. I drove down to pick up the machine a couple days later. The machine had belonged to a family friend of the seller. She was fondly referred to as Aunt and the family was cleaning out her estate.

When I first saw the machine, I was impressed with its condition. There were a couple minor scratches to the paint, but overall it looked like it had been used maybe 2 or 3 times. The seller had it set up so that I could try it before purchasing. I turned the hand wheel and could tell that the machine was dry, but everything else looked good. The seller had the original case so I happily packed up the machine and drove home, smiling all the way.

|

| Case with key and plenty of goodies |

At home, I unpacked the entire case so that I could take inventory of its contents. Neatly packed along with the machine was the foot control and power cord, extension tray, knee lift, instruction manual, record of purchase in 1969, the guarantee card not filled out, advertisements, a parts list, extra purchases from the store in 1979 and the green accessories tray.

|

| Instruction manual |

|

| Take note, this Bernina was originally purchased by J. Singer |

|

| We have exceeded the 30 guarantee term |

|

| On back of picture: "The BERNINA is a mountain of overwhelming beauty, and the dream of Alpinists all over the world to ascend to its summit, Piz BERNINA. BERNINA is also the name of the queen of Swiss sewing machines and thus the dream of innumerable women all over the world." |

|

| Parts list for new 730 Record |

|

| Bernina bag with a few tears in its side |

|

| Two receipts, one for the needles pictured and the other for the bobbins pictured |

|

| Tray fits snuggly on the back of the machine |

|

| Drawers filled with goodies |

I first contacted Neal at NIT, Inc. in February of 2017 looking for a replacement motor. My machine would sew for about 10-15 seconds at a time and then slow and stop. Neal is one of the Bernina specialists at NIT, Inc. All of the specialists there were specifically trained by Fritz Gegauf AG in the early 1970's and know how to handle these now vintage machines. I had tried different power cords, changed the belts, and cleaned the motor brushes, but nothing fixed the problem. Neal had a couple suggestions for me to try as well, but ultimately I decided to ship my EPL motor to him so he could fix the bad field winding. In under two weeks, Neal emailed to say that the motor was fixed. He explained what he had done and let me know what changes in operations I could expect with the new motor.

The rebuilt motor function will now be as follows:

Max speed is normal with the motor switch on MAX.

Min switching now provides an off/on condition, something that this machine needed in the first place.

In March, after trying out my new motor, I emailed Neal again to say that I was still experiencing problems. He was so thorough in trying to diagnose the problem and had me send multiple photos so that he could see key parts of my machine. We both saw a crack in the vertical shaft gear. Originally, I said that I would like to try to tackle replacing this gear myself and Neal sent the link to one of his videos. After watching the video though, I decided that repair was beyond my skills and I boxed up my machine to send to Neal so that he could work on it. In June, I sent the machine packed in one box and the power cord and foot control in another box. Along with vertical shaft gear replacement, Neal said that he would be repairing the needle position piston detent, replacing the bobbin winder, and checking the foot control power.

While he was working on the machine Neal was nice enough to give me updates through his Facebook website. He sent me this link so I could check on his progress. I loved being able to see my machine and if you have time I suggest you check out the NIT, Inc website. It has a wealth of information and some great pictures on there.

|

| Newly unwrapped machine upon its return from Utah |

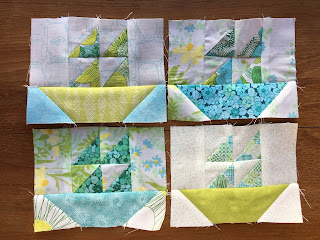

When Neal was done with my machine he shipped it back to me and it arrived in nearly pristine condition. I was so excited to see my machine, it was BEAUTIFUL. I have only used the machine on a couple projects so far, but it has performed very well. There was a bit of an adjustment period for me as to the level of noise the machine makes. It is noticeably louder than my Necchi Supernova or my Pfaff 131, but it is a constant and comforting sound. It reminds me that my machine is powerful and could work very hard if need be but is, for the most part, content to tackle the quilt piecing I have provided thus far.

The foot control is still the original and I intend to use that as long as possible. The max/min speed control is non-selective now and the motor is always set to max speed. This is not as fast as some of my other machines, but well-suited to almost anything I would be working on.

|

| Foot control |

The new bobbin winder works well and a repair on the needle piston detent now allows me to move my needle right-left-center to varying degrees.

|

| Bobbin winder |

|

| R-L-C needle position any time I want to now |

Here are a few final pictures of the machine set up and ready to go. I'm so glad this machine joined my collection, she and I will have many sewing adventures in the coming years.

|

| The tray has minimal wear |

|

| Beautiful coming and going |